VITOLEN

111 UVR

First choice for use under high UV radiation

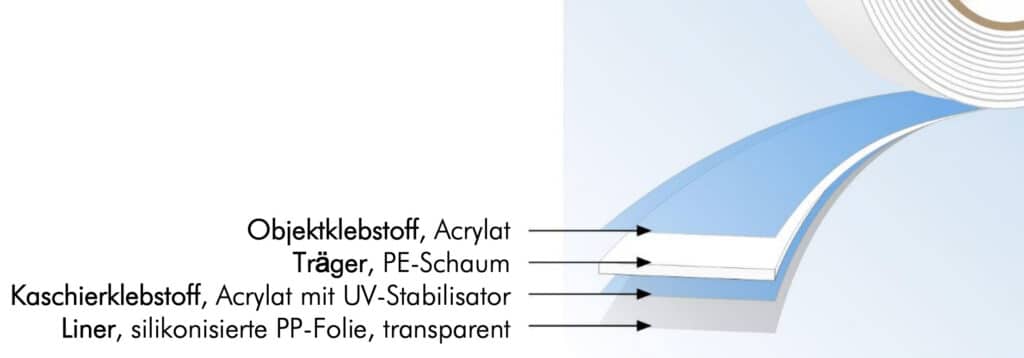

VITOLEN 111 UVR (UV-resistant) is the material of choice when the product is exposed to high levels of UV radiation. Among other things, it was developed as a UV-stable heat protection tape for foil greenhouses / tunnels, where it protects the foil against thermal and mechanical damage. For this purpose, metal frame work as well as its sharp-edged areas are covered by the one-sided self-adhesive VITOLEN 111 UVR before applying the greenhouse / tunnel foil.

Application

Due to the acrylic adhesive treated with a UV stabilizer, the UV radiation does not damage the foam of VITOLEN 111 UVR, so that it does not disintegrate despite intense sunlight.

Extensive tests have shown that the laminated film of the tape is also protected by this adhesive.

The high-end acrylic adhesive is in itself resistant to UV, aging, weathering and temperature, in contrast to the commonly used inexpensive caoutchouc-based adhesives.

Product benefits

- High UV resistance

- Good adhesion on different surfaces

- The closed-cell foam absorbs nearly no moisture

- Resistant against water and a large number of usual chemicals

- Very good thermal insulation properties

- Easy and quick application without rubish – no liner to be disposed-off

Excerpt of the weathering test

Parameters: 8 hours of UVA radiation and 4 hours of condensation alternately.

The literature (1) provides the rough correlation for UVA-340 lamps: 1.000 hours (42 days) corresponds to about one year of outdoor use.

PE foam, white, 3 mm, 33 kg/m³

|

PE-foam, unprotected |

|

PE-foam with 45 µm PP-film, laminated onto the foam with rubber-based hot-melt adhesive. after 63 days of weathering |

|

VITOLEN 111 UVR |

Summary

Unprotected PE foams are severely damaged within approx. 3 years of outdoor weathering and then show recognizable cracks and furrows.

Products that are laminated with low-cost hot-melt rubber adhesives, as used up to now, show this behavior after a much shorter time.

By adding a suitable UV stabilizer in a high-end acrylate pressure-sensitive adhesive, no change in the surface can be observed even after more than 3,000 hours of accelerated aging.

List of references

- Brennan, Gregory R. Fedor and Patrick J. Comparison Between Natural Weathering and Fluorescent UV Exposures. [Online] 30. 11 2023. https://www.q-lab.com/documents/public/bc750e56-b4d6-41fc-a5a1-2a163b4ba5a3.pdf.

Processing instructions

The most important processing parameters and information on cleaning are listed in our Information on Processing Adhesive Tapes. Processing

Storage and shelf live

12 months after receipt of goods, when stored non processed, at room temperature (20°C + 3°C) and 40% - 60 % relative humidity, in original packaging

Individual

You cannot find the right product?

Would you like a different thickness, width or even cutting dies?

Do you need a special adhesive for your application?

Would you like to have your own company branding?

We manufacture individual solutions, depending on the quantity.

Uncomplicated and perfectly designed for your use.

Talk to us!