VITOFLEX

CM-L

Protecting, damping, insulating and sealing.

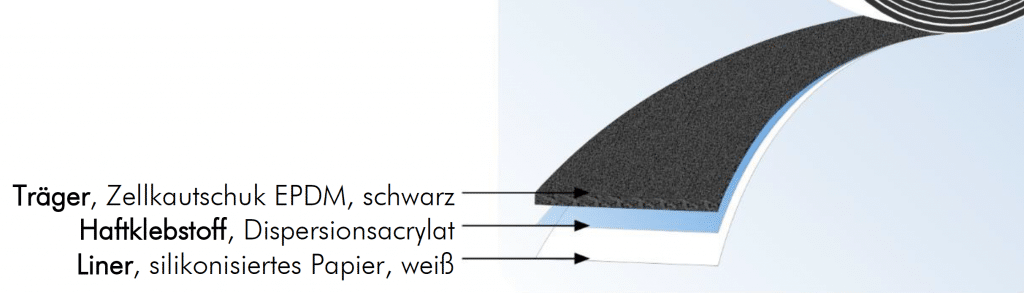

VITOFEX CM-L is a one-sided self-adhesive, flexible cellular rubber with a closed-cell structure, based on EPDM (Ethylene Propylene Diene Rubber). VITOFLEX CM-L is resistant against many acids and alkalics in usual concentrations, water and water vapour up to 100°C, seawater, potassium and sodium compounds (for example common salt solution), alum in aqueous solution, cleaning agents, photo chemicals, cold ammoniac, acetylene, alcohols, glycerine, brake fluids and antifreeze fluids based on glycol, carbonic acid, ozone, silicone oil and grease, chloride of lime in aqueous solution, wet and dry chlorine gas, hot ammoniac and hydrochloric acid.

Resistant to

Acids and alcalics in usual concentrations, water and water vapour up to 100°C, seawater, potassium and sodium compounds (for example common salt solution, aqueous alum solutions, detergents, photo chemicals, cold ammoniac, acetylene, alcohols, glycerine, brake fluids and antifreeze fluids based on glycol, carbonic acid, ozone, silicone oil and grease, chloride of lime in aqueous solution, and others.

Limitedly resistant to

Chlorine gas wet and dry, ammoniac hot, concentrated hydrochloric acid.

Not resistant to

Oils, fats, white spirit, solvents such as toluene, dichloromethane, trichloroethene, tetrachloroethene, nitro thinner, nitric acid, concentrated sulfuric acid.

Product benefits

- very good aging and ozone resistance

- Good resistance to chemicals

- Closed cell structure, watertight

- Excellent weathering resistance

- High temperature resistance (40 °C to 120 °C)

- excellent flexibility

Processing instructions

The most important processing parameters and information on cleaning are listed in our Information on Processing Adhesive Tapes. Processing

Storage and shelf live

6 months after receipt of goods, when stored non processed, at room temperature and 60 % relative humidity, in original packaging

Technical data and product properties

Density (ISO 845)

130 (±20) kg/m³

Compressive strength (ASTM D 1056)

20 - 50 kPa

Compression set

(DIN 53 517)

22 h / 50 % / 23 °C

25 %

Shrinkage

24h at + 70°C and 10 mm thickness

max. 5 %

water absorption

(DIN 53 428)

max. 5 %

Corrosion behavior

(DIN 53 428)

on bare silver:

on bare copper:

strong corrosion, wide corona

strong corrosion, wide corona

Fire behavior foam

(FMVSS 302)

passed

Temperature resistance

-40 °C to +120 °C

Individual

You cannot find the right product?

Would you like a different thickness, width or even cutting dies?

Do you need a special adhesive for your application?

Would you like to have your own company branding?

We manufacture individual solutions, depending on the quantity.

Uncomplicated and perfectly designed for your use.

Talk to us!